Ageless® (Oxygen Absorber)

AGELESS®, from Mitsubishi Gas Chemical is the world’s first oxygen absorber. AGELESS® is a small oxygen absorbing sachet used

to extend shelf life by taking out oxygen of a sealed package. One of the objective in doing so is preventing the growth of

Insect and Mold. AGELESS® can be found in many different types of application from pharmaceuticals formulation to industrial

metals to food application (which has the largest consumption).

In an oxygen-free environment, AGELESS® are tools that help to keep you products fresh without all the unhealthy preservatives

and maintain the taste as original as possible.

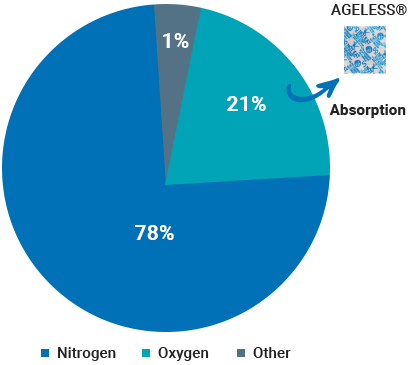

Function

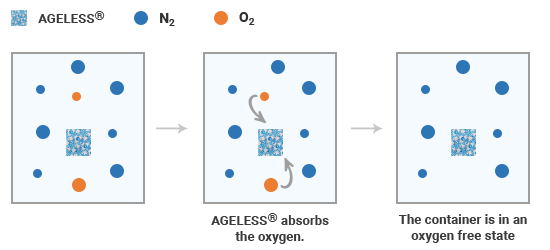

AGELESS® absorbs all oxygen in a sealed container to create an oxygen free condition (maintain an oxygen concentration of 0.1%

or less). As AGELESS® absorbs more oxygen, the volume decreases and the gas remaining in the sealed container becomes mostly

nitrogen, an inert gas.

How does AGELESS® work (simplified)

The World’s Top Brand of Oxygen Absorbers

AGELESS® – The World’s Top Brand of Oxygen Absorbers

AGELESS® from Mitsubishi Gas Chemical is the world’s first oxygen absorber. Conventional technologies such as conventional

vacuum and gas replacement packaging are unable to achieve very low oxygen environment (< 0.1%). This is now possible through

the use of AGELESS®. AGELESS® is a simple but effective way to maintain the original flavor, color, fragrance and nutrition of

freshly prepared food as well as dramatically extend shelf life. Using AGELESS® is extremely easy which is why a number of food

and pharmaceutical products are using it.

Type of AGELESS®

Features

There is a variety of AGELESS®, each designed for a specific task.

| Type | Feature | Main Application | Water activity (AW) of product to be applied |

|---|---|---|---|

ZPT

|

Standard iron Type | Doughnuts, cakes, fresh cakes, brandy cakes, salami, beef jerky, pet foods and the like. | 0.95 or less |

Z-PKC

|

Standard iron Type | Coffee, tea, nuts, dried vegetables, spices, laver (seaweed), and pharmaceutical products. | 0.65 or less |

S

|

Fast Acting Type | Processed Meat, Cheese, Pizza, Tortillas | 0.65 to 0.95 |

SS

|

Fast Acting Type | Frozen and refrigeration food | 0.65 to 0.95 |

E

|

O2 and CO2 Absorbing type | Coffee | 0.3 or less |

GLM

|

Organic Non-iron Type | Ham, Sausage, Chicken Nuggets. Products that are run through a metal detector | 0.3 to 0.95 |

Advantages of using AGELESS®

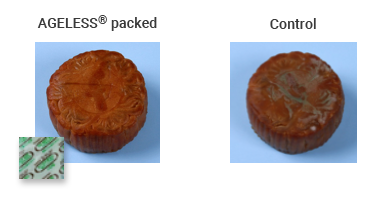

Prevention of Mold Growth

Highly-Moist foods are easy to get moldy. However, mold cannot grow under oxygen-free condition. With the use of AGELESS®, the

moisture content of your food is not affected and Mold growth is prohibited.

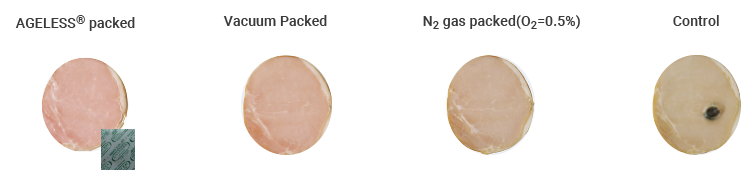

Color

Original color of fresh food are bright, however this color will change as time progress due to the presence of Oxygen. AGELESS®

can be used to maintain the original color for a longer term by removing oxygen.

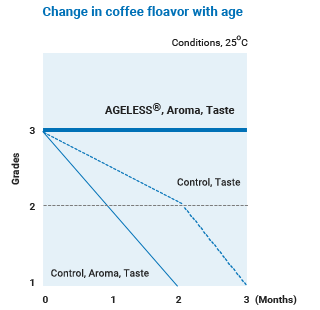

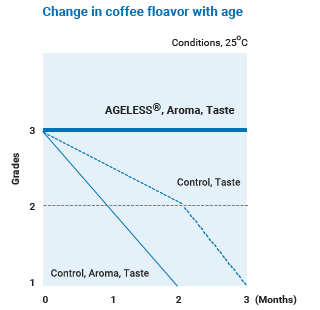

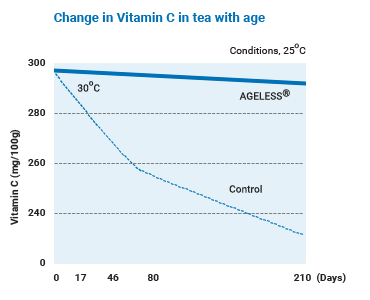

Flavors and Vitamin

The well-loved rich aroma of Coffee & Tea are lost due to oxidation. With the use of AGELESS®, these original fresh aroma and

flavor can be retained.

Oil

Oil becomes rancid due to Oxidation and these oxidized oil are not healthy to human body. AGELESS® has been shown to be able to

prevent this oxidation.

Insects

AGELESS® is able to eliminate both insects and eggs without pesticide. Therefore, there is no worries about residual pesticide.

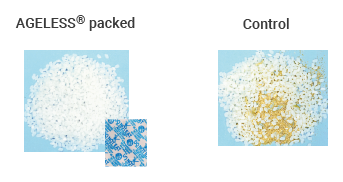

Nutrition

Nutritional values of Vitamin C, Vitamin E is also deteriorated. AGELESS® is able to retain these important nutrients.

Automation

AGELESS® is also available in roll and strip form. This allows quick and effective dispensing in any number of products. We work

closely with our customers to enable efficient and safe automation regardless whether standard and custom design dispensers are

being used.

Please send us a message in the Contact Us section to find out more about our dispenser leases.

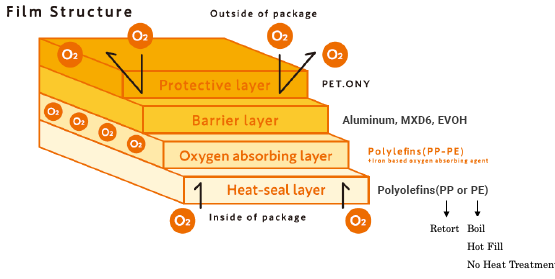

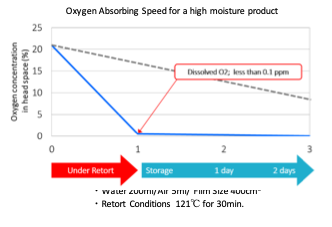

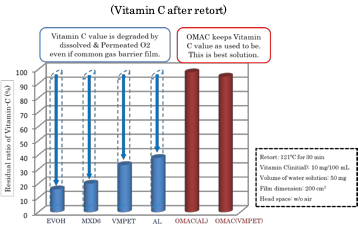

Oxygen Absorbing Film “AGELESS OMAC®”

Traditionally, there was no solution to extend the shelf life of liquid or wet food. In order to help our customer who are

manufacturing liquid base product, AGELESS OMAC® has been developed to help foods remain fresh for an extended periods of time after

heat sterilization such as boiling or retort. After numerous tests, it was found that AGELESS OMAC® could also work with products

with a water activity as low as 0.5 on top of wet or liquid product.

AGELESS OMAC® is the next level in oxygen absorber technology which can be used various food production ranging from moist products

like baked goods to liquid based soups and sauces.

Features

AGELESS OMAC® has been originally designed to be used with products that have a high water activity and would be subjected to heat

treating in order to speed up the oxygen absorbing process.

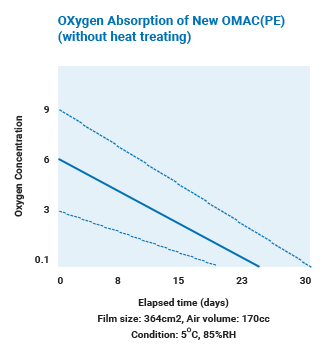

However, by changing the sealing layer, it was found that AGELESS OMAC® can also work with products that only had mid-level water

activity (Aw<0.5) and therefore heat treatment such as retort is no longer necessary. This discovery has allowed AGELESS OMAC® to be

considered in many new applications.

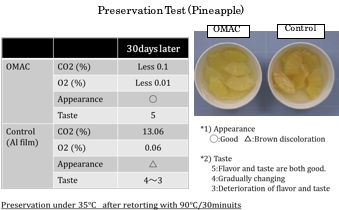

Retaining taste and color

AGELESS OMAC® will prevent discoloration; rancidity and ensure the product stay fresh longer.

Mitsubishi Gas Chemical Singapore

Mitsubishi Gas Chemical Singapore